At AAA Metals, we provide turnkey metal solutions. From sourcing the raw material to converting and finishing it, we deliver metal ready to use in manufacturing projects.

Precision sawing—also referred to as precision saw cutting—is one of our specializations. Using the process, we cut a variety of materials in bar, pipe, plate, and tube form. Regardless of whether a customer needs small or large parts or a prototype or production run, we can meet their needs with quality cut products.

Our Precision Sawing Capabilities

Our precision sawing capabilities accommodate a variety of customer project specifications.

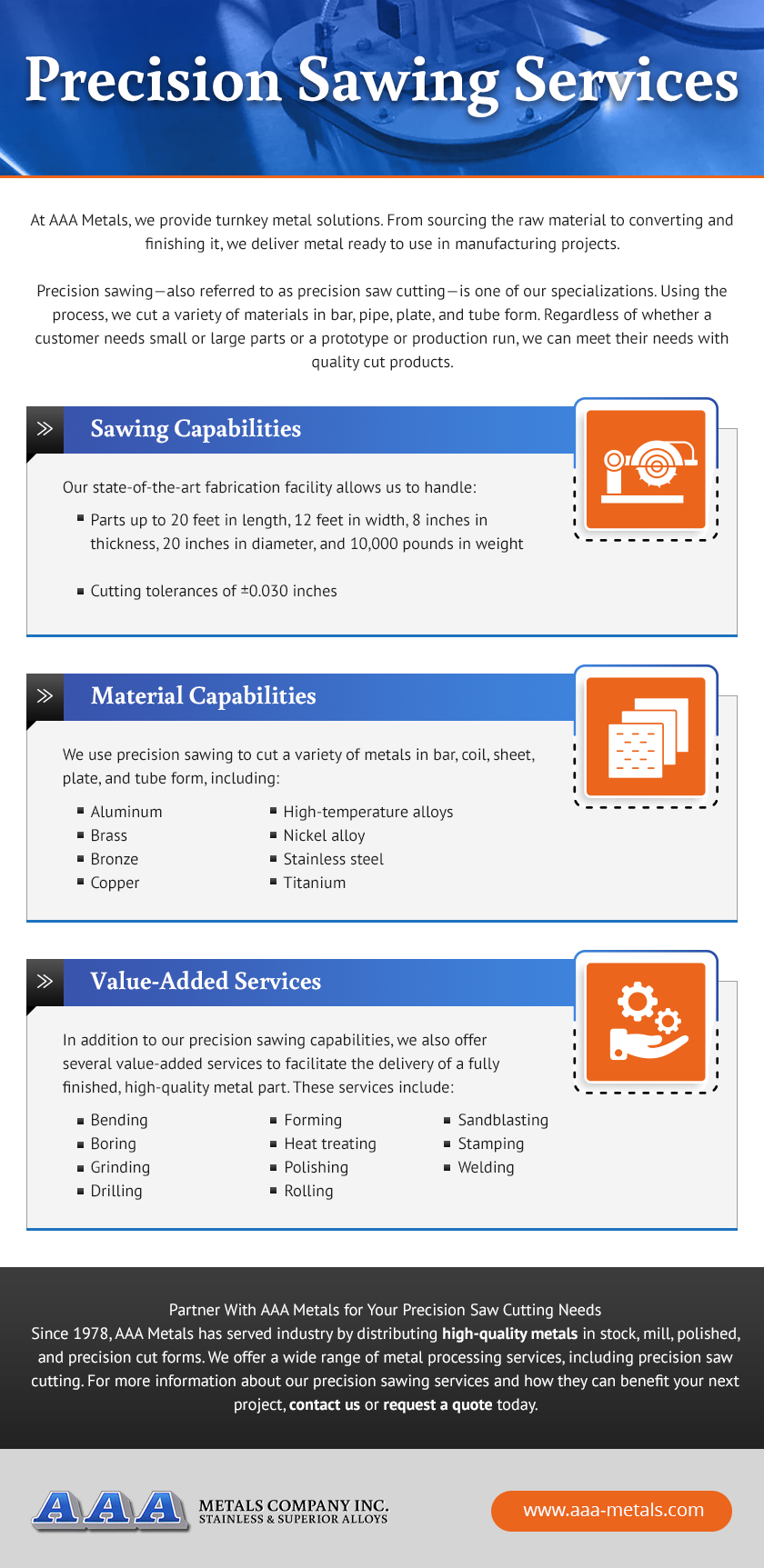

Sawing Capabilities

Our state-of-the-art fabrication facility allows us to handle:

- Parts up to 20 feet in length, 12 feet in width, 8 inches in thickness, 20 inches in diameter, and 10,000 pounds in weight

- Cutting tolerances of ±0.030 inches

Material Capabilities

We use precision sawing to cut a variety of metals in bar, coil, sheet, plate, and tube form, including:

- Aluminum

- Brass

- Bronze

- Copper

- High-temperature alloys

- Nickel alloy

- Stainless steel

- Titanium

Value-Added Services

In addition to our precision sawing capabilities, we also offer several value-added services to facilitate the delivery of a fully finished, high-quality metal part. These services include:

- Bending

- Boring

- Grinding

- Drilling

- Forming

- Heat treating

- Polishing

- Rolling

- Sandblasting

- Stamping

- Welding

Every part we produce is also subjected to comprehensive inspection and testing to ensure both quality and accuracy. These procedures include visual and dimensional inspection and surface and ultrasonic testing.

Overview of Precision Metal Saw Cutting

Metal sawing is a manufacturing process that employs a saw blade to cut a large metal workpiece into smaller pieces. It finds application across a wide range of industries as a cutting method for a variety of materials, ranging from aluminum to titanium. Depending on the requirements and restrictions of the cutting project, industry professionals use different sawing methods.

Precision Sawing Cutting Methods

There are two primary saw cutting methods employed by manufacturers today:

- Circular saw cutting. In this technique, a circular blade spins as it cuts through the workpiece. Many circular saws are designed for rigidity and reduced vibration levels, which means that manufacturers can cut parts faster and with more precision.

- Band saw cutting. Band saw machines contain an extended straight blade that has evenly distributed metal teeth. Band saws provide uniform cutting action and high precision results and are highly suitable for cutting workpieces into irregular or customized shapes.

Advantages of Precision Saw Cutting

Compared to other metal cutting methods, precision saw cutting offers several advantages, such as:

- Reduced material waste (due to closer tolerance cutting)

- Quicker turnaround (without sacrificing cut quality)

- Higher quality cut finishes (reducing the need for further finishing operations)

Industrial Applications of Precision Saw Cutting

Precision saw cutting finds use across a diverse set of industries, including:

- Aerospace

- Architectural

- Biotechnology

- Chemical

- Food processing

- Marine

- Packaging

- Pharmaceutical

Partner With AAA Metals for Your Precision Saw Cutting Needs

Since 1978, AAA Metals has served industry by distributing high-quality metals in stock, mill, polished, and precision cut forms. We offer a wide range of metal processing services, including precision saw cutting. For more information about our precision sawing services and how they can benefit your next project, contact us or request a quote today.

- Complete Precision Sawing for Bar, Pipe, Tube & Plate

- Up to 20″ x 30′ long

- Capabilities from 8″ Thick x 96″ x 144″

- Cut-Off Services Available