Choose the Best Stainless Steel Tubing Type for Your Application

Stainless steel is an iron-based alloy characterized by a chromium content of at least 10.5%. Depending on the grade, stainless steel can also contain additional alloying elements such as molybdenum, nickel, aluminum, and titanium. These elements are added in various proportions to enhance specific properties.

Due to chromium’s strong affinity for oxygen, a self-renewing layer of chromium oxide forms on the surface of stainless steel when the material is exposed to oxygen. This chromium oxide layer acts as a barrier that protects the underlying material from corrosive elements in the environment. The higher the proportion of chromium, the quicker the corrosion-resistant barrier can replenish itself.

In addition to its inherent resistance to corrosion, stainless steel provides the following advantages:

- High strength-to-weight ratio

- Hygienic, easy-to-clean surface

- Aesthetically appealing appearance

- Resistant to high temperatures

- Highly amenable to cutting, forming, machining, and welding

Stainless Steel Tubing Grades

Stainless steel is available in over 200 grades, ranging from the widely used austenitic grades to the more specialized low-carbon, high-chromium ferritic grades. Despite the wide variety of grades available, 304 and 316 continue to be the most frequently used grades for fabricating tubes, plates, and other stainless steel products. While both of these grades are classified as austenitic steels, they each have distinct metallurgical attributes that make them suitable for specific applications.

- 304/304L stainless steel. 304 stainless steel is a highly versatile and inexpensive stainless steel exhibiting great strength and corrosion resistance. A relatively high proportion of nickel makes 304 stainless steel more formable and weldable than many other grades. 304L stainless steel contains less carbon than the standard 304 alloy, making it easier to form and weld but lower in strength.

- 316/316L stainless steel. 316 stainless steel contains a higher proportion of molybdenum, which increases its corrosion and temperature resistance. These attributes make 316 steel particularly well-suited for harsh and corrosive outdoor applications. As a low-carbon version of 316 stainless steel, 316L stainless steel has a slightly lower tensile strength and yield strength but is more amenable to the welding process.

Common Applications

While thicker-walled stainless steel pipes are stronger and better suited for high-load structural applications, stainless steel tubes are perfect for decorative or architectural applications that benefit from a lighter weight and less expensive solution. Common stainless steel tubing uses include:

- Architectural structuring

- Rails and ladders

- Food processing equipment

- Marine applications

- Automotive components

- Fluid handling systems

Project Example – Polished Stainless Steel Decorative Column Covers

Project Example – Polished Stainless Steel Decorative Column Covers

AAA Metals partnered with a client in the retail industry to create 24 decorative column covers from 14-gauge stainless steel. Featuring a bright, reflective finish, these 8″ diameter tubes were designed to convey a high-end, modern aesthetic while providing an easy-to-maintain surface. Their flawless finish was achieved by thoroughly removing the surface scale of the hot-rolled annealed and pickled surface, then grinding out the weld joint and using non-metal abrasives to achieve an Ra 32 polished surface.

Leveraging our diverse metal fabrication and polishing skills, we overcame challenges related to the light wall tubing and cross-sectional ovality of the column covers. This required careful optimization of several details, from choosing the most appropriate consumables to employing the right grinding and polishing techniques. A diamond tip surface tester was used to measure roughness and ensure that the finish met the customer’s specifications.

AAA Metals, Your Trusted Stainless Steel Tubing Supplier

Offering one-stop-shop stainless steel converting and polishing capabilities, AAA Metals works with customers in several industries to create custom stainless steel tubes for various projects. The seamless and polished appearance of our tubing products makes them perfect for a range of decorative architecture and infrastructure applications. By sourcing high-quality starting materials and meticulously cutting, grinding, and polishing the tubes to the desired specifications, we make sure the final product meets the customer’s aesthetic and technical requirements.

Stainless Steel Polishing Services

Metal polishing is the process of smoothing the surface of a fabricated metal part to prepare it for its intended application. With stainless steel tubing and piping, polishing the internal and external surfaces is critical for eliminating small cracks or crevices in which bacteria or other contaminants could accumulate. Having a smooth, polished surface also extends the surface life of stainless steel tubing and piping.

While stainless steel can be inherently difficult to polish, AAA Metals has the experience and skill to achieve smooth, blemish-free finishes on a range of stainless steel tubing products. The requested finishing standard will generally determine the types of abrasives used and the number of steps required to complete the polishing process. To avoid surface damage, we gradually increase the smoothness of the finish by using abrasives with grit strengths ranging from 50-3,000.

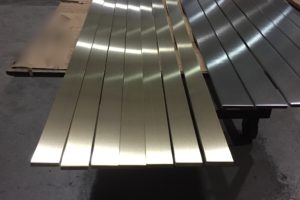

Our Square & Rectangular Tubing Capabilities

AAA Metals can shape and polish stainless steel square and rectangular tubing to meet virtually any specification. Our specific tubing capabilities include:

- Stainless steel grades. 304, 304L, 316, and 316L

- Finish options. Mill Finish, Grit Pol, and Pol & Buff

- Other tubing material options. Aluminum, bronze, and brass

- Polished (as shown)

Contact Us for Your Custom Tubing Needs!

From low-maintenance railing to decorative column covers, stainless steel tubing is a cost-effective and durable solution for both structural and aesthetic applications. AAA Metals works with clients from various industries to create high-quality stainless steel square and rectangular tubing in a range of sizes, grades, and finishes. With our in-house polishing, grinding, and cutting capabilities, we deliver end-to-end solutions that are carefully tailored to meet each customer’s needs. This comprehensive approach gives us the flexibility to accommodate challenging or highly specialized projects that would be difficult or impossible for other companies to complete.

To learn more about our polished stainless steel tubing options, please contact us today or request a quote.