At AAA Metals Company Inc., we specialize in metal supply and metal processing services. Since 1978, we’ve served clients in diverse industries ranging from aerospace to packaging with high-quality raw materials like stainless steel, nickel alloy, brass, copper, bronze, titanium, and specialty grades or difficult-to-find metals. Along with being a stainless steel pipe supplier, we offer stock metal, mill-form metal, and precision-cut metal segments in the following additional forms:

- Flat bars

- Hex Bar

- Round Bar

- Square Bar

- Angles

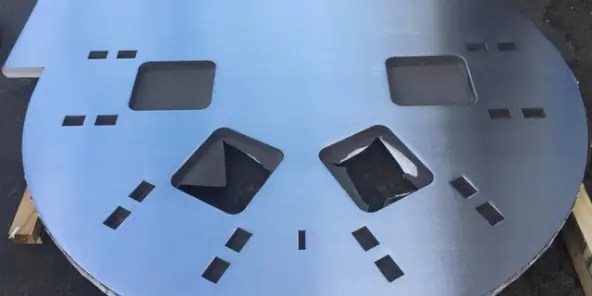

- Plates

- Sheets

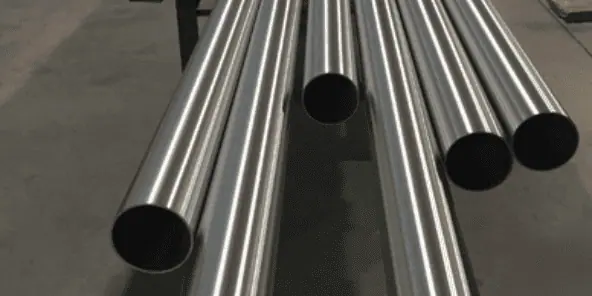

- Pipe and Tubes

- Square and Rectangular Tubing

We couple our extensive material offerings with a range of core and value-added in-house services to provide comprehensive metal solutions for our customers. From cutting, sawing, and shearing to welding, heat treating, and polishing, our full-service company is here to address your unique material and finishing needs.

Industries We Serve at AAA Metals

The AAA Metals team has the resources, background, and expertise to meet the material demands of diverse industries.

Aerospace

This industry relies on corrosion-resistant stainless steel and other aerospace-grade alloy metals. They lend aircraft components a durable strength for optimal longevity and reliable performance. Given the flight-based applications within this sector, these materials’ light weight is advantageous in aerospace projects. The same is true of their ability to withstand the extreme and fluctuating temperatures and pressures to which aerospace parts and equipment are exposed without suffering degradation. Such materials help aerospace manufacturers comply with the industry’s strict quality and safety requirements. Utilizing equipment like digital readouts and laser measurement systems to ensure precision, our cutting, shearing, and sawing services enable us to achieve the tight tolerances necessary to support our aerospace customers at ±0.005 inches.

Architectural

Stainless steel and related alloy metals are common within architectural applications because of their superior strength and load-bearing capabilities. These versatile metals are also prized for their sleek, pleasing aesthetic, which is a desirable element for architectural projects. Through our stainless steel polishing services, AAA Metals can provide metals with a smooth finish that resist abrasion, environmental conditions, and oxidation for lasting durability.

Pharmaceutical/Biotech

The pharmaceutical and biotech markets make use of non-toxic metals like stainless steel and aluminum for their beneficial properties, such as biocompatibility and resistance to chemicals and corrosion. Stainless steel in particular is well suited to hygienic pharma and biotech environments because it’s also inert and simple to sterilize so that it will hold up against repeated cleanings. Using polished stainless steel for these sectors enhances contamination prevention, as you minimize pits and crevasses that could otherwise promote microbial growth. Stainless steel has common pharma and biotech applications as the material composition for tanks, mixers, and reactors.

Chemical

Aluminum is a typical choice for the chemical industry. It’s lightweight and affordable yet offers good mechanical strength and resistance to corrosion and chemicals. Stainless steel is another common option, meeting the demands of a wide variety of petrochemical and chemical applications due to its ability to resist corrosion when faced with gaseous and aqueous substances or high-heat environmental conditions. Also, its nonreactive nature is beneficial for any components that will come in direct contact with chemicals.

Manufacturing and Fabrication

Similar to other industries, the manufacturing and fabrication sectors use stainless steel in equipment and parts often because of its durability, strength, and thermal and corrosion resistance. In addition to stainless steel, other common material selections include aluminum, brass, bronze, copper, nickel alloy, and titanium, all of which are available in a variety of finishes. AAA Metals offers a range of fabrication services and value-added capabilities to give our manufacturing and fabrication clients the benefit of turnkey solutions. These capabilities include the following:

- Assistance with metal stock selection

- Laser and waterjet cutting

- Centerless and double disc grinding

- Polishing

- Heat treating

- Precision sawing and shearing

Food Processing

Stainless steel’s corrosion resistance makes it an ideal choice for a wide variety of applications in the food processing industry, as well. The FDA has strict regulations regarding the materials and equipment that are acceptable to use in food-contact applications, and such metals facilitate cleaning and don’t experience degradation in the face of frequent sterilization. Food-grade metals like certain varieties of stainless steel are safe to use around consumable goods as they won’t infuse foods or beverages with their taste, smell, or coloring. Stainless steel’s different grades provide varying degrees of resistance to corrosion, allowing for material versatility when creating simple or complex shapes.

Marine

Marine-grade stainless steel offers enhanced corrosion resistance over standard varieties, as it maintains its strength even in the presence of saltwater or when exposed to acidic conditions. The makeup of the material affects its capacity for resisting such environments, as corrosion resistance improves in stainless steel as its chromium or molybdenum content increases. Another corrosion-resistant material, marine-grade aluminum has applications in this sector as well for its optimal strength-to-weight ratio.

Packaging

A product’s packaging is often the customer’s first impression of your goods. Not only should it be visually attractive and of good quality, but it must also protect your product’s integrity on shelves and in transit. The packaging industry typically employs alloy metals like aluminum, stainless steel, tin-free steel, and tin plate for their durable reliability. To make packaging options like foil wraps, cans, and pouches, this market utilizes these versatile alloy metals in semi-rigid or rigid formats.

Stainless Steel and Superior Alloys by AAA Metals

When you’re looking for reliable alloy metal and stainless steel distributors to support your industry’s latest project, turn to the team at AAA Metals. As an industry-leading stainless steel pipe supplier and service provider, we are committed to offering quality certified materials at competitive prices to fit your budget. We can accommodate your needs for complying with AMS, ASME, ASTM, QQS, and MIL-S specifications.

Our warehouse’s large inventory and our worldwide distribution network allow us to make “on time” deliveries. We can handle virtually any size inquiry, and AAA Metals does not have a minimum order quantity. We pride ourselves on our customer service. Contact us to learn more about the metals and services we offer, and how the AAA Metals team can support your individual operation or project.