Unlike standard machinery, marine equipment must endure sea air and salt spray for long periods, rusting at a faster rate for reduced operational efficiency. Stainless steel, while naturally resistant to corrosion, may still underperform in harsh marine conditions.

Marine-grade stainless steel, then, is the answer for coastal and other related applications. This variety of stainless steel boasts a particular strength, ruggedness, and high corrosion resistance compared to other metals. Read on to learn more about corrosion and the types of marine-grade stainless steel that best resist it in marine projects.

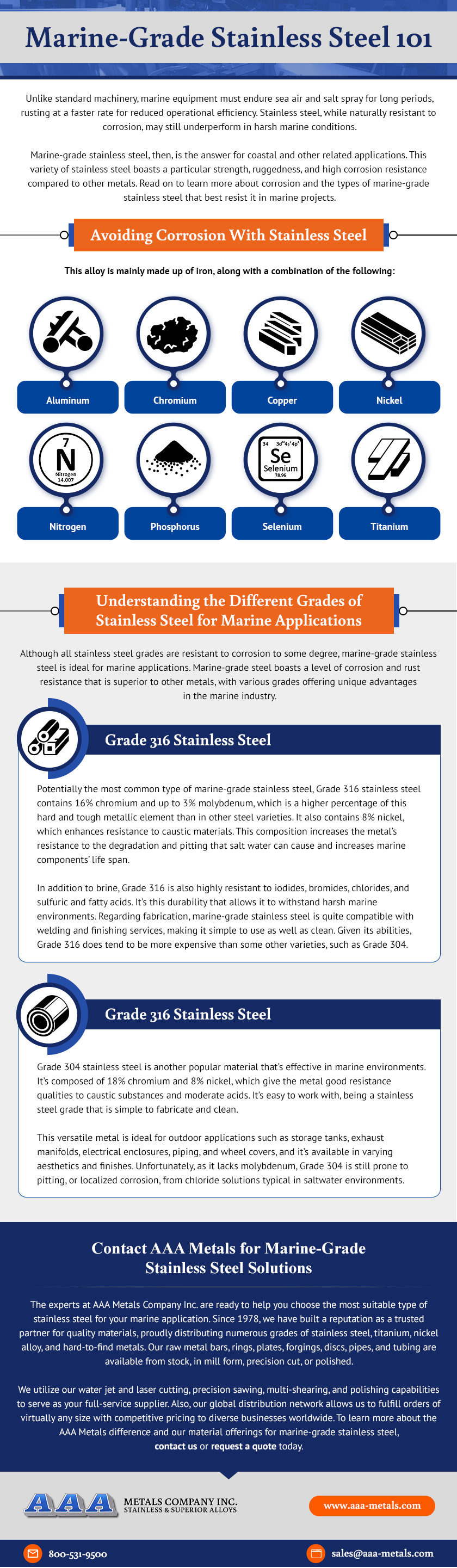

Avoiding Corrosion With Stainless Steel

In marine environments, salt is among the biggest threats to metal. It’s a highly corrosive substance, and salt spray from the sea can be a real problem for equipment in coastal operations. Through the chemical process of oxidation, iron molecules in steel produce flaky oxides on the metal’s surface when oxygen and iron molecules come into contact with water, causing deterioration. Corrosive elements like salt degrade steel components, most often in the form of rust.

One of the most common ways to avoid metal degradation is to use stainless steel, which is renowned for its anti-corrosive qualities. This alloy is mainly made up of iron, along with a combination of the following:

- Aluminum

- Chromium

- Copper

- Nickel

- Nitrogen

- Phosphorus

- Selenium

- Titanium

It’s the chromium that is primarily responsible for corrosion resistance at 10.5% or more of stainless steel’s material composition. A protective skin of chromium oxide forms on the material’s surface to safeguard the base metal against moisture exposure, preventing iron oxide and rust from forming.

Understanding the Different Grades of Stainless Steel for Marine Applications

Although all stainless steel grades are resistant to corrosion to some degree, marine-grade stainless steel is ideal for marine applications. Marine-grade steel boasts a level of corrosion and rust resistance that is superior to other metals, with various grades offering unique advantages in the marine industry.

Grade 316 Stainless Steel

Potentially the most common type of marine-grade stainless steel, Grade 316 stainless steel contains 16% chromium and up to 3% molybdenum, which is a higher percentage of this hard and tough metallic element than in other steel varieties. It also contains 8% nickel, which enhances resistance to caustic materials. This composition increases the metal’s resistance to the degradation and pitting that salt water can cause and increases marine components’ life span.

In addition to brine, Grade 316 is also highly resistant to iodides, bromides, chlorides, and sulfuric and fatty acids. It’s this durability that allows it to withstand harsh marine environments. Regarding fabrication, marine-grade stainless steel is quite compatible with welding and finishing services, making it simple to use as well as clean. Given its abilities, Grade 316 does tend to be more expensive than some other varieties, such as Grade 304.

Grade 304 Stainless Steel

Grade 304 stainless steel is another popular material that’s effective in marine environments. It’s composed of 18% chromium and 8% nickel, which give the metal good resistance qualities to caustic substances and moderate acids. It’s easy to work with, being a stainless steel grade that is simple to fabricate and clean.

This versatile metal is ideal for outdoor applications such as storage tanks, exhaust manifolds, electrical enclosures, piping, and wheel covers, and it’s available in varying aesthetics and finishes. Unfortunately, as it lacks molybdenum, Grade 304 is still prone to pitting, or localized corrosion, from chloride solutions typical in saltwater environments.

Contact AAA Metals for Marine-Grade Stainless Steel Solutions

The experts at AAA Metals Company Inc. are ready to help you choose the most suitable type of stainless steel for your marine application. Since 1978, we have built a reputation as a trusted partner for quality materials, proudly distributing numerous grades of stainless steel, titanium, nickel alloy, and hard-to-find metals. Our raw metal bars, rings, plates, forgings, discs, pipes, and tubing are available from stock, in mill form, precision cut, or polished.

We utilize our water jet and laser cutting, precision sawing, multi-shearing, and polishing capabilities to serve as your full-service supplier. Also, our global distribution network allows us to fulfill orders of virtually any size with competitive pricing to diverse businesses worldwide. To learn more about the AAA Metals difference and our material offerings for marine-grade stainless steel, contact us or request a quote today.