Stainless Shape Weights

Density factor of .2836 per cubic inch (Plate products may be heavier)

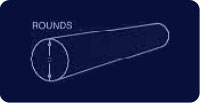

Lbs. per lineal foot = 2.6729 x D2

Lbs. per lineal inch = .22274 x D2

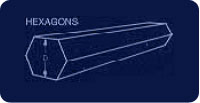

Lbs. per lineal foot = 3.4032 x D2

Lbs. per lineal inch = .2836 x D2

Lbs. per lineal foot = 2.9473 x D2

Lbs. per lineal inch = .2456 x D2

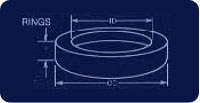

Wt. of Ring in Lbs. =

.22274 x T x (OD2-ID2)

Wt. of Ring in Lbs. =

.22274 x T x (OD2-ID2)

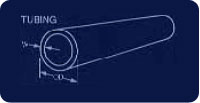

Lbs. per lineal foot = 10.68 x (OD-W) x W

Lbs. per lineal inch = 89 x (OD-W) x W

Weight Conversion Factors

(For estimating purposes only) To obtain theoretical weights of metals and alloys – Calculate the weight of the appropriate shape from above – Then multiply by the appropriate factor.

| Aluminum | .364 | Inconel 600 | 1.074 | Nickel 200 | 1.134 |

| Aluminum Alloys | .356 | Inconel 625 | 1.082 | Nitronic Alloys | 1.000 |

| Brass | 1.080 | Inconel 718 | 1.029 | Rene 41 | 1.057 |

| Columbium | 1.107 | Inconel X-750 | 1.053 | Tantalum | 2.142 |

| Copper | 1.148 | Invar | .97 | Titanium | .582 |

| Copper Alloys | 1.120 | Magnesium | .223 | Titanium Alloys | .576 |

| Hastelloy "B" | 1.187 | Molybdenum | 1.321 | Tool Steels | 1.000 |

| Hastelloy "C" | 1.139 | Monel 400 | 1.127 | Tungsten | 2.464 |

| Hastelloy "X" | 1.056 | Monel 405 | 1.127 | Tungsten Hi-Speed | 1.120 |

| Haynes 25 (L-605) | 1.172 | Monel 500 | 1.078 | Tungsten-Moly | 1.040 |

| Haynes "188" | 1.183 | Multimet (N-155) | 1.056 | Waspalloy | 1.057 |

| Incoloy 800 | 1.025 | Mumetal | .317 | Zirconium | .835 |