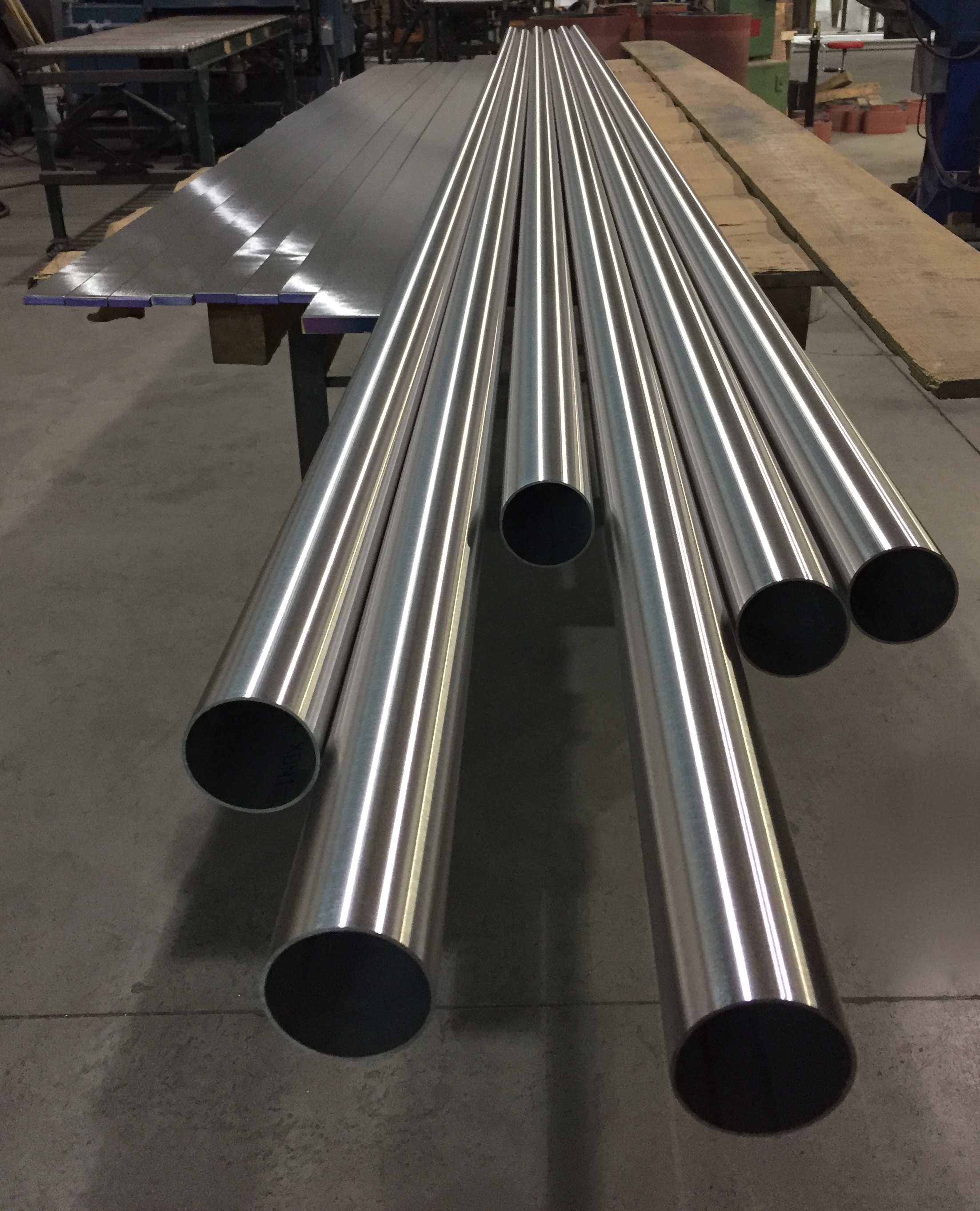

At AAA Metals, our vast inventory of raw metal components includes pipes, tubing, bars, discs, forgings, plates, and rings. Our pipe and tubing selections are available in a wide range of stock lengths and diameters, and we can cut lengths of pipe and tubing to order specifications.

At AAA Metals, our vast inventory of raw metal components includes pipes, tubing, bars, discs, forgings, plates, and rings. Our pipe and tubing selections are available in a wide range of stock lengths and diameters, and we can cut lengths of pipe and tubing to order specifications.

Having the right metal for the job is essential. That’s why we offer the following options for our metal stock:

- Welded. Welded pipes are fabricated from cut lengths of plate, which are rolled in a rolling machine to create a cylinder with touching edges along one point of the cylinder’s circumference. The edges are welded together to create a fused, hollow pipe. Tubing, however, can be manufactured from endless coils slit to the desired width and rolled in a continuous line until touching edges meet and fuse together.

- Seamless. Seamless pipes or tubes are formed from solid cylinders, or billets. A mandrel is directed through the billet to hollow out the form. We finish seamless pipes and tubes by rolling and stretching the metal to meet the final desired specifications of the order.

- Milled and Polished. We offer both mill finishing and polishing in a variety of grit levels for a rough or smooth finish. Finer grit polishing offers higher resistance to corrosion and wear-related damage.

- Stainless Steel Grades. Our stainless steel pipe and tubing are available in many grades, including 301, 302, 304, 304L, 309, 310, 316, 316L, 321, 330, and 347.

- Tube Shapes. Depending on the grade of stainless steel selected, we supply tubing in rectangular, round, and square shapes.

Our in-house experts can help you choose the right products based on the dimensional and environmental requirements of your application.

Pipe vs. Tube — Choosing the Best for Your Application

The terms pipe and tube are often used interchangeably, but they’re different products intended for different functions. A good way to distinguish between pipes and tubes is by how they’re measured. As a general rule, pipes transport and distribute fluids and gases, so they’re measured by their capacity to do so based on their nominal pipe size. Pipes need to have reliable pressure ratings, ductility, and yield strength so they can be trusted with pressurized or heated fluids.

Tubes are usually measured by outside diameter and wall thickness in standard units. They need to meet strict mechanical strength and dimensionality requirements for use in pressure equipment, instrumentation systems, and mechanical applications.

Stainless Pipe & Tube Applications

Stainless steel is a popular metal due to its resistance to corrosion, its strength to weight ratio, and its long lifespan with minimal maintenance requirements. Some of the industries and applications that rely on high-quality stainless steel pipe and tubing include:

- Marine. Stainless steel can withstand the harsh, corrosive environment in marine settings. While most 300 series stainless steels work for marine applications, 316 stainless steel is particularly resistant to chlorides, acids, and brine. Our metal products can be used for boat and pier supports, railings, and more.

- Pharmaceutical. Our stainless steel pipes can be used for sanitary pipes and pipe fittings. These resist corrosion, can be easily sanitized at high temperatures, and don’t allow buildup to develop when properly polished.

- Handrails. Stainless steel tubing is useful for handrails. Its advantages include resistance to impact and wear, ideal characteristics for frequent contact and use, and resistance to the elements. Because of its strength, it can form sturdy handrails with slim profiles.

AAA Metals: A Quality Stainless Steel Pipe & Tube Supplier

At AAA Metals, we specialize in fabricating and supplying high-quality pipes and tubes that cater to our clients’ application requirements and specifications. Our products are AMS, ASTM, ASME, MIL-S, and QQS certified to ensure optimal quality and adherence to industry standards.

Our Polishing and Custom Cutting Services

At AAA Metals, we provide a wide range of polishing, cutting, and finishing services. Our value-added services include bending, drilling, cutting, milling, welding, polishing, and more.

For more information, or to get started on your pipe and tube solutions, contact us or request a quote today.