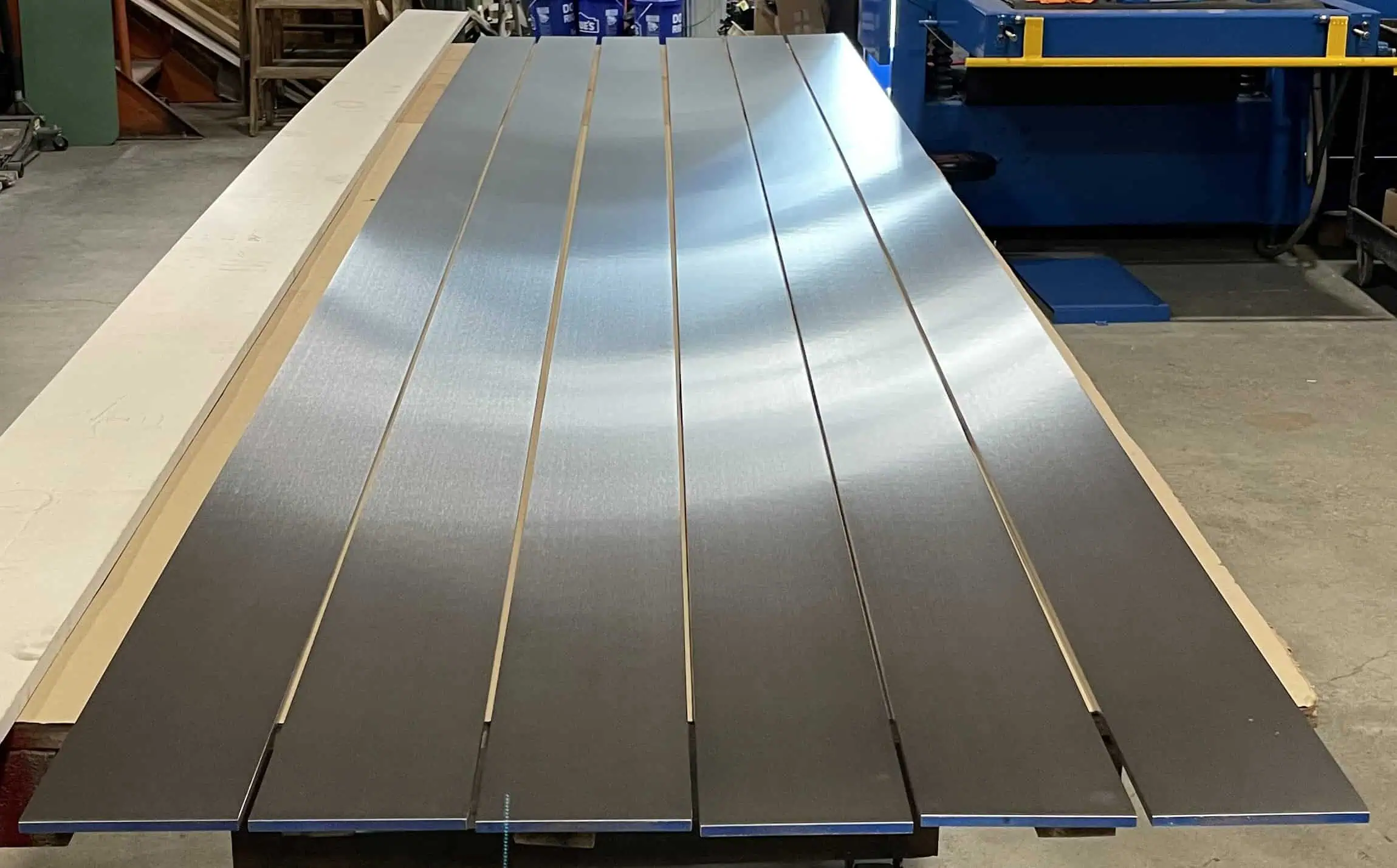

Due to its unique physical qualities and aesthetic appeal, stainless steel stock is a high-demand material for many industries. At AAA Metals Company, we offer many types of stainless steel grades in shapes that meet diverse application requirements. On this page, you can learn more about the characteristics of stainless steel and our complete range of product offerings.

What Is Stainless Steel?

Stainless steel refers to a family of iron-based alloys that contain a minimum of 10.5% chromium. While other alloying elements are also added, chromium is the element that allows stainless steel to exhibit superior corrosion resistance compared to other types of steel. Stainless steel forms a durable, self-healing oxide film when scratched.

In addition to chromium, stainless steel features varying levels of carbon, nickel, molybdenum, magnesium, and nitrogen according to the specific grade. Certain grades are chosen based on the performance requirements of the end-use environment. Depending on the grade, stainless steel can reliably withstand temperatures ranging from cryogenic to 2,000 °C (3,632 °F). With small adjustments to its alloying elements, stainless steel can achieve a range of ductility, tensile strength, and other characteristics.

Grades of Stainless Steel

As a leading stainless steel stock distributor, AAA Metals Company carries an extensive selection of stainless steel grades. The grading system for stainless steel differentiates alloys based on their composition and characteristics. You can learn more about the series and grades we carry below.

-

300 Series

The 300 series features austenitic stainless steels that are all iron-based chromium-nickel alloys. They offer excellent wear resistance, corrosion resistance, strength, and formability. Each grade in this series features slight chemical composition differences that result in unique performance capabilities.

-

301

301 Stainless steel 301 is a high-strength, corrosion-resistant grade with an attractive finish. Since it resists abrasion and is highly malleable, it is often used for decorative structural applications.

-

302

302 Stainless steel This grade features a similar composition to grade 304 but with higher carbon levels. Grade 302 is valued for its ability to resist chemicals, acids, and corrosive solvents. It is used in food processing equipment and medical applications, among other uses.

-

304

304 Stainless steel 50% of the world’s steel is grade 304 stainless steel. This durable and aesthetically pleasing material features 8% nickel and 18% chromium. Grade 304 should not be exposed to salt water, as this can cause crevices and pitting. We carry this grade in sheets and steel plates.

-

309

309 Stainless steel This grade features the same machinability as 304 but with improved tensile strength and chemical resistance. Due to its ability to withstand very high temperatures, it is often used in aircraft engines, furnace components, automotive exhaust systems, and other high-heat applications.

-

310

310 Stainless steel Grade 310 stainless steel resists oxidation under mildly cyclic conditions up to 2,000 °F. It features a high chromium and nickel content that results in excellent toughness, low magnetic permeability, and superior corrosion resistance.

-

316

316 Stainless steel Stainless steel 316 is the second most commonly produced steel and features 2% to 3% molybdenum. This allows it to resist saline better than other grades. Common applications involve surgical tool production and use in outdoor coastal environments.

-

321

321 Stainless steel This grade can withstand temperatures up to 1,500 °F, with enhanced creep and rupture resistance. Since it will not lose structural integrity under extreme conditions, it is used in demanding applications, such as aircraft piston engine components.

-

301

- 400 Series

400 series stainless steels have at least an 11% chromium content and 1% more manganese than the 300 series. The grades within this series also have a higher carbon content, which produces a martensitic crystalline structure in the finished material. 400 series stainless steels are high-strength and highly wear-resistant, but they do not resist corrosion as well as austenitic types.

-

405

405: This grade features additional aluminum content that prevents it from fully hardening after welding. It offers less corrosion resistance than grade 430 and is only suitable for mildly corrosive environments. Grade 405 is often used to produce steam nozzles and quenching racks.

-

409

409: Grade 409 offers corrosion resistance and high-temperature tolerance. Since it resists atmospheric corrosion and exhaust gas, it is often used in automotive exhaust systems.

-

420

420: Containing 12% chromium, this grade is bright and highly corrosion-resistant. Since its chemical composition optimizes strength and hardness, grade 420 is often referred to as blade-grade steel and is a popular choice for making surgical instruments.

-

430

430: This widely available grade is easy to form but cannot withstand extreme temperatures or corrosion. Since it does not contain nickel, it is less expensive than other options, like grade 304. 430 stainless steel is often used in decorative automotive trim applications, backyard barbecue grills, and more.

-

440

440: Also referred to as razor blade steel, grade 440 is a high-carbon chromium steel with the highest hardness level of any stainless steel grade. It can be hardened to Rockwell 58 hardness and resists mild acids as well as alkalis.

-

405